Understanding Conveyor Rollers: Types, Applications, and Benefits

Conveyor rollers are essential components in material handling systems, providing the rolling mechanism that allows products and materials to move smoothly and efficiently along a conveyor belt or system. These rollers are used across a wide range of industries, including manufacturing, warehousing, logistics, food processing, and mining, due to their versatility and ability to streamline operations.

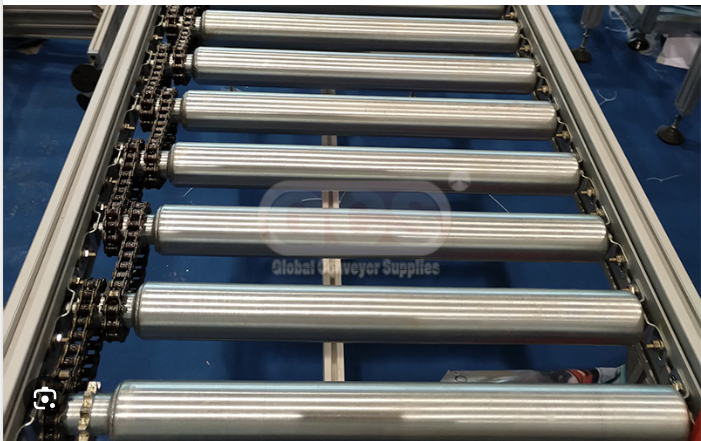

What Are Conveyor Rollers?

Conveyor rollers are cylindrical components installed within a conveyor frame, designed to support and move loads along a conveyor system. They rotate either freely or are powered to facilitate the movement of goods, helping reduce manual labor and improve workflow efficiency.

Types of Conveyor Rollers

There are several types of conveyor rollers, each suited to different operational requirements:

- Gravity Rollers

- Operate without motor power.

- Rely on gravity or manual force to move objects.

- Ideal for lightweight or short-distance applications.

- Operate without motor power.

- Powered Rollers (Motorized)

- Include internal motors to drive the roller.

- Used in automated systems for consistent and controlled movement.

- Often found in high-speed or high-volume operations.

- Include internal motors to drive the roller.

- Grooved Rollers

- Designed with grooves to guide belts or lines.

- Common in assembly lines where product tracking is essential.

- Designed with grooves to guide belts or lines.

- Tapered Rollers

- Used on curved conveyor sections.

- Help maintain alignment while navigating turns.

- Used on curved conveyor sections.

- Plastic and Stainless Steel Rollers

- Plastic rollers are lightweight and corrosion-resistant, used in food or packaging industries.

- Stainless steel rollers are durable and ideal for harsh or hygienic environments.

- Plastic rollers are lightweight and corrosion-resistant, used in food or packaging industries.

Applications of Conveyor Rollers

Conveyor rollers are used in systems for:

- Packaging and distribution centers

- Automotive assembly lines

- Airport baggage handling

- E-commerce fulfillment centers

- Mining and aggregate transport

- Food and beverage processing

Their ability to transport goods quickly and safely makes them indispensable in environments where speed, safety, and accuracy matter.

Benefits of Using Conveyor Rollers

- Increased Efficiency: Reduces the need for manual handling, speeding up the workflow.

- Cost-Effective: Especially gravity rollers, which require no power source.

- Scalable: Systems can be expanded or modified as operations grow.

- Reduced Risk of Injury: Automating material movement minimizes strain on workers.

- Customizable: Rollers can be tailored in terms of size, material, and load capacity.

Conclusion

Whether you’re moving small packages in a warehouse or large mining materials across a site, conveyor rollers are a key component of any efficient material handling solution. Choosing the right type of roller for your application can significantly enhance productivity, reduce operational costs, and improve safety standards. When investing in or upgrading a conveyor system, understanding the function and options available for conveyor rollers is essential to making the right decision.